IT

Laser technology has been used in the IT industry for a few years now and it has helped many consumer electronics companies to provide better products for their customers. Laser technology helps manufacturers improve the efficiency and quality of their product. Laser engraving, laser marking is the most common technology used on IT products and many manufacturers alike use lasers to mark logos and two-dimensional code on their products.

Auto Parts

Laser processing technology is an advanced technology of automobile production, which has been applied to make high-quality car accessories as well as fitting signs for years. Laser engraving, laser engraving, laser etching, technology, laser welding as well as laser cutter, are widely applied in the automobile industry.

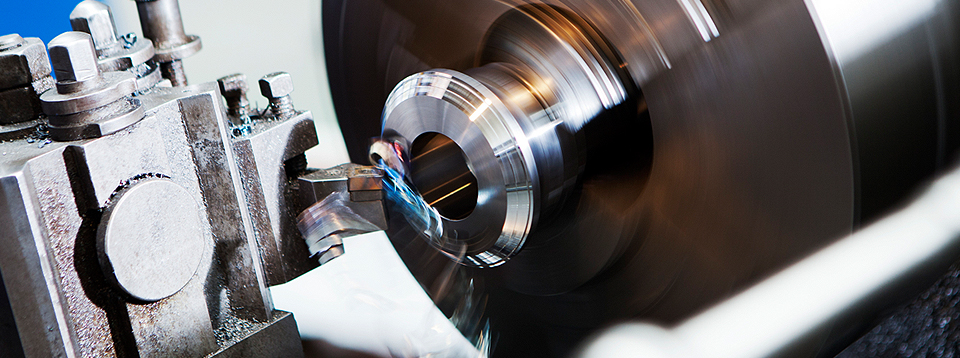

Hardware

The application of laser in the Hardware Process Industry has become more and more extensive. The Laser helps people make a high-quality and secure mark on various kinds of materials, cut out tool shapes, or even makes a different carving of different depth on the surface of metals.

Gift & Accessory

At present, lasers have a wide range of uses in Gemology and Jewelry Processing. It is to drill precious stones, cut diamonds of complex shapes, groove original stones, mark on the surfaces and accomplish subtle welding etc. Productions made by lasers are elegant, smart, environment-friendly, and don’t need any after treatment.

Special Application

Silicon wafer slicer is mainly applied in the solar battery industry and the semiconductor industry. The laser is able to slice, cut or groove on the surfaces of silicon, polysilicon, germanium and gallium arsenide etc. The technology will not damage any side of the silicon, nor the performance of the product. As a result, the manufacturing efficiency, as well as production efficiency is greatly improved.