Metal Laser welding

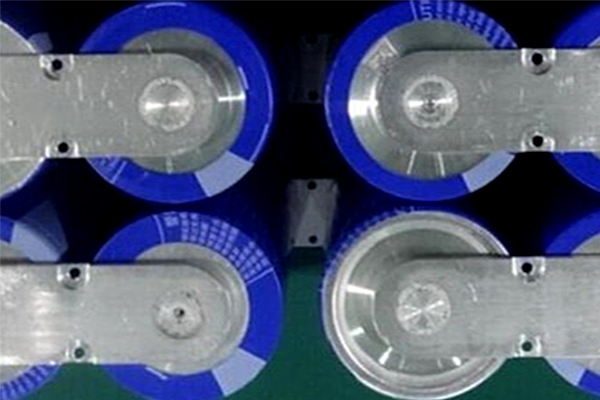

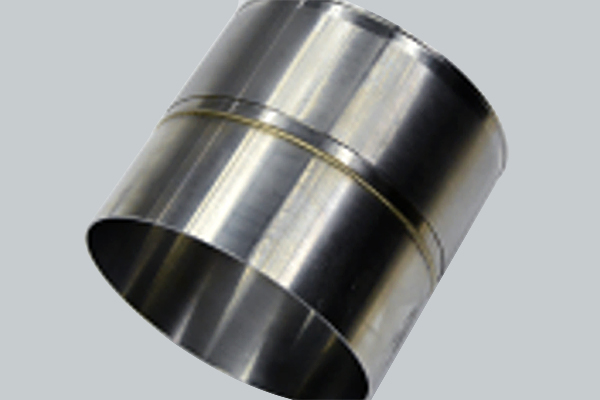

This equipment is capable of performing spot welding, fillet welding, lap welding, and overlap welding along arbitrary trajectories—including single points, straight lines, arcs, and full circles—on materials such as carbon steel, stainless steel, aluminium alloy, and galvanised sheet. It finds application in industries including battery modules, sheet metal fabrication, 3C electronics, instrumentation, and automotive components.

Features

- The HW1008 series laser welding machine can perform seam welding, fillet welding, lap welding, and stack welding with arbitrary trajectories such as single points, straight lines, arcs, and full circles on materials including carbon steel, stainless steel, aluminium alloy, and galvanised sheet metal;

- The welding head comes standard with a 2D galvanometer welding head, with an optional oscillating welding head available. It delivers high-quality welds that are stable, reliable, and aesthetically pleasing;

- The equipment is applicable to industries including battery modules, sheet metal processing, 3C electronics, instrumentation, and automotive components;

- It can be integrated with rotary axes, simple turntables, and custom fixtures to achieve automated welding.

Specifacation

| Name | Specifications/Parameters |

| Fiber Laser Power | 1500W / 2000W / 3000W / 4000W |

| Laser Wavelength | 1080±5nm |

| Power Adjustable Range | 10~100% |

| Power Stability | ±1% |

| Laser Modulation Frequency | 50KHz |

| Fiber Length | Standard: 15m / Standard: 20m |

| Fiber Connector | QBH |

| Laser Operating Mode | Continuous/Modulation |

| Welding Head | Standard: 2D Galvanometer Head; Optional: Oscillation Welding Head |

| Control System | Han’s Standard |

| Maximum Processing Range | X-axis: 1000mm, Y-axis: 800mm, Z-axis: 500mm |

| X/Y/Z Single Axis Linear Module Positioning Accuracy | ±0.02mm |

| X/Y/Z Single Axis Linear Module Maximum Speed | 250mm/s |

| Average Power Consumption | 7.5kwh / 9.5kwh / 14.5kw / 19kwh |

| Machine Weight | Approx. 500kg (without chiller) |

| Operating Environment Temperature | 10~40℃ |

| Operating Environment Humidity | <70% |

| Power Requirements | AC220V, 50Hz / Three-phase, AC380V, 50Hz |

| Overall Cabinet Dimensions | L1800×W1555×H2435mm (excluding tricolor light and boom height) |

Application