HOUSE FURNISHINGS

Laser processing solutions for house furnishings

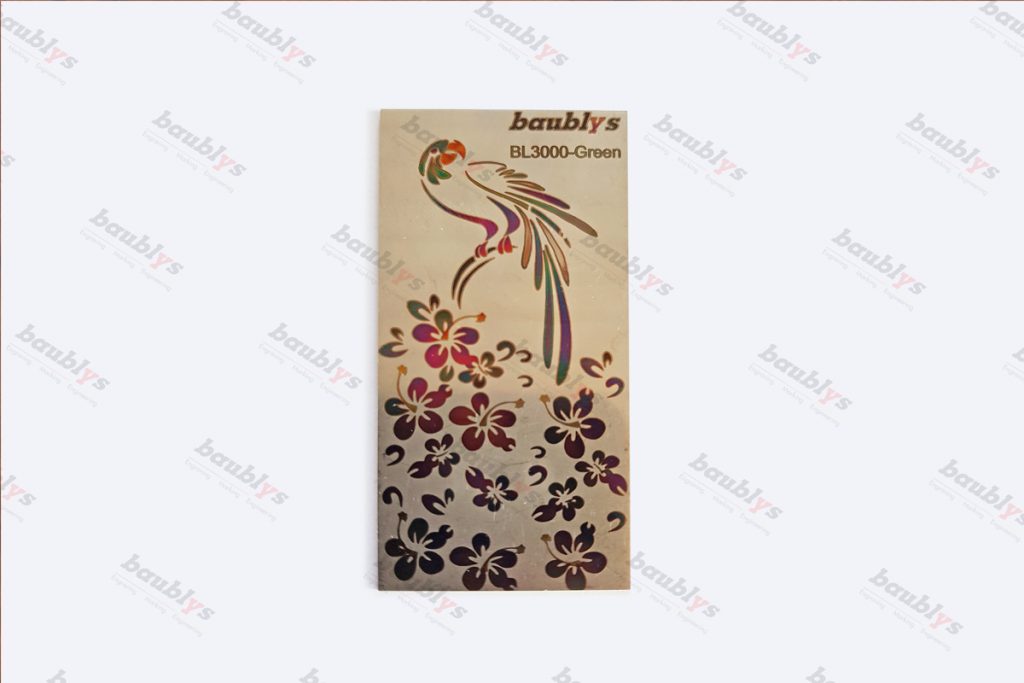

Lights, cups, home appliances, home decorations and so on, everything could be processed by laser. The technology is now widely used in the house furnishing industry. People use the laser to cut out demanded parts, and produce fine markings on their products.

In the production of raw materials and finished products, these can be marked from the beginning with, for example, a serial number or a 1D & 2D code in an efficient and environmentally friendly manner. This guarantees an always complete quality assurance and a clear identification. For example, in wooden, plastic, and aluminum windows.

In the field of design products, with the help of a laser system, a manufacturer’s logo, design contours, consecutive serial number as well as 1D & 2D codes can be marked on the product for marketing purposes.

High efficiency is achieved by an extremely flexible laser marking system, which adapts quickly to changing requirements. The possibilities of the marking contents (serial numbers, codes, logos, etc.) as well as the possible laser marking methods and the marking on many different materials makes the use of the laser flexible and economical.

Possible laser marking methods:

- Annealing

- Marking and cutting foils

- Colored annealing

- Color / anodizing and paint removal

- Surface structuring

- Marking

- Deep engraving

- 3D deep engraving

- Laser cutting

- Foaming

- Carbonization

Some other application examples

More applications on house furnishings industry

- Marking logos

- Marking of design contours

- Door handles, fittings, and much more

- Marking and cutting of foils

- Cutting materials

- Production of frosting, surface structuring and texture

- Automation with conveyor belt, rotary table or robot

- Round parts with scales, serial numbers and logos

- Marking of raw materials and finished products (for example windows, door locks, etc.)

- Marking of housing, single or complete components, injection molded parts, plastic and rubber parts

Advantages

High efficiency is achieved by an extremely flexible laser marking system, which adapts quickly to changing requirements.

High economic efficiency, identification, traceability, quality assurance through testing with integrated camera, database connection with feedback of the labeling, high quality, durable and permanent marking, optimal and long-lasting readability.