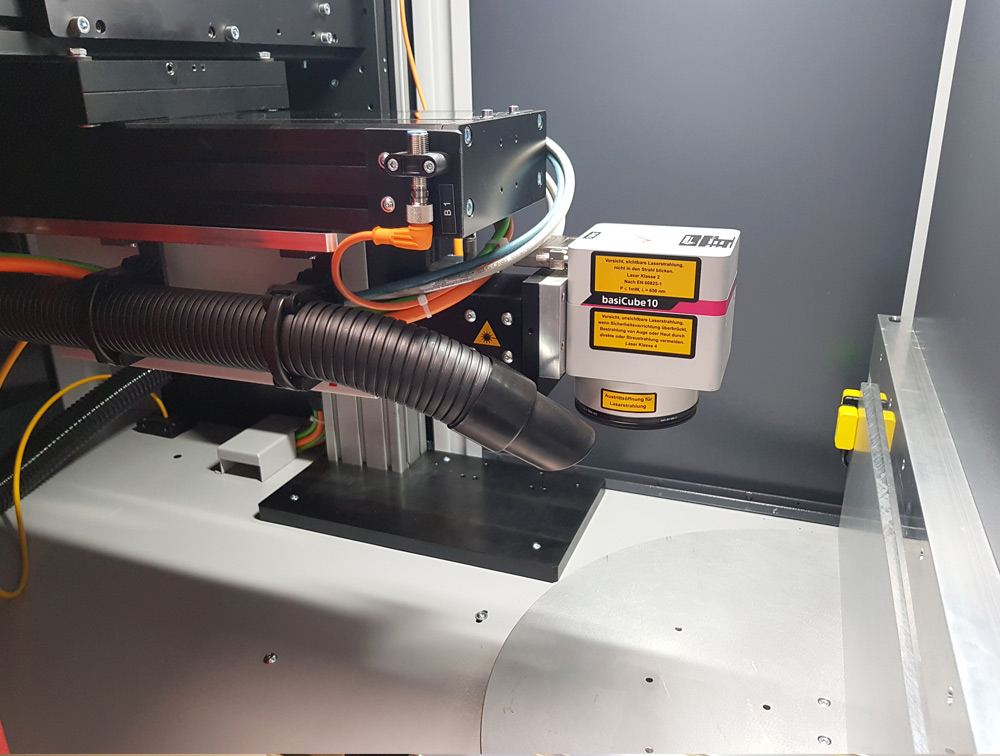

UV Laser Marking/ Engraving Machine BL5000 series

Features

- Good beam quality, extremely small focused laser spot, small heat-affected zone enabling ultra-fine marking;

- maximum working area by using of axes, up to. 480 x 480 mm

- CNC-controlled Z-axis, the setting of the focus can be done conveniently and within a very short time

- Touch screen facilitates the operation.

- Fully encapsulated machine, comply with laser protection class 1, no further safety installations are necessary for its operation.

- Optional turntable for semi-automatic solutions. Loading/unloading times are reduced to almost zero.

Application

- Widely used in LOGO marking of high-end electronic products; Food, PVC, medical packaging materials (HDPE, PO, PP, etc.) marking and drilling (d≤10μm); Flexible PCB board marking and slicing; Metal or non-metallic coating removing; Silicon wafer micro-hole and blind hole processing; Marking of low-voltage apparatus and refractory materials

Specifications

| Laser type | UV laser |

| Wavelength | 355 nm |

| Pulse repetition frequency | 10 – 200 kHz |

| Power | 4 – 25 W |

| Marking area | on request |

| Control | CNC control |

| System software | Windows 7 |

| Measurements | 1493 x 860 x 1777 mm (L x W x H) |

| Network connection | Yes |

Samples

marking on wire

marking on air switch

electronic product logo marking

FPC cutting

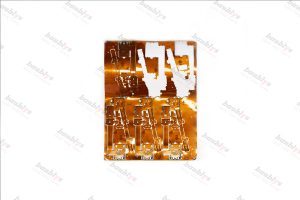

IC cutting

PCB cutting

marking on remote control

marking on glass surface

marking on light bulb surface

marking on plastic bottle cap

marking on plastic needle cylinder

carbonize on plastic shoe surface

Materials

| Material | Engrave | Cut |

| Stainless Steel | √(up to 0.3mm) | √(up to 0.1mm) |

| Coated Metals | √(up to 0.3mm) | √(up to 0.1mm) |

| Anodized Aluminum | √(up to 0.3mm) | √(up to 0.1mm) |

| Brass | √(up to 0.3mm) | √(up to 0.1mm) |

| Copper | √(up to 0.3mm) | √(up to 0.1mm) |

| Gold | √(up to 0.3mm) | √(up to 0.1mm) |

| Silver | √(up to 0.3mm) | √(up to 0.1mm) |

| Titanium | √(up to 0.3mm) | √(up to 0.1mm) |

| Bare Metals | √(up to 0.3mm) | √(up to 0.1mm) |

| Ruber | √(up to 0.3mm) | √(up to 0.1mm) |

| PES | √(up to 0.3mm) | √(up to 0.1mm) |

| PS | √(up to 0.3mm) | √(up to 0.1mm) |

| PP | √(up to 0.3mm) | √(up to 0.1mm) |

| ABS | √(up to 0.3mm) | √(up to 0.1mm) |

| PVC | √(up to 0.3mm) | √(up to 0.1mm) |

| PE | √(up to 0.3mm) | √(up to 0.1mm) |

| Acrylic | √(up to 0.3mm) | √(up to 0.1mm) |

| MDF | √ | |

| Wood | √(up to 0.3mm) | √(up to 0.1mm) |

| Granite | √(up to 0.3mm) | √(up to 0.1mm) |

| Marble | √(up to 0.3mm) | √(up to 0.1mm) |

| Brick | ||

| Glass | √(up to 0.3mm) | √(up to 0.1mm) |

| Fiber Glass | √(up to 0.3mm) | √(up to 0.1mm) |

| Crystal | √(up to 0.3mm) | √(up to 0.1mm) |

| Ceramic | √(up to 0.3mm) | √(up to 0.1mm) |

| Diamond | √(up to 0.3mm) | √(up to 0.1mm) |

| Gemstone | √(up to 0.3mm) | √(up to 0.1mm) |

| Cloth | √(up to 0.3mm) | √(up to 0.1mm) |

| Leather | √(up to 0.3mm) | √(up to 0.1mm) |

| Fiber | √(up to 0.3mm) | √(up to 0.1mm) |

| Carbon Fiber | √(up to 0.3mm) | √(up to 0.1mm) |

| Nylon | √ | |

| Epoxy | √ | |

| HDPE | √ |