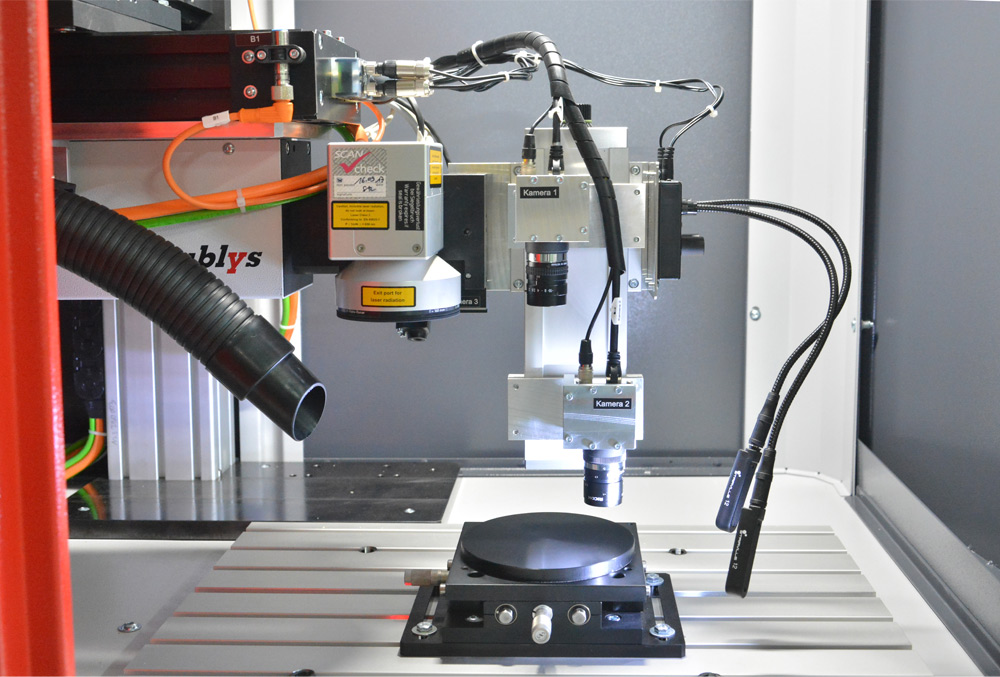

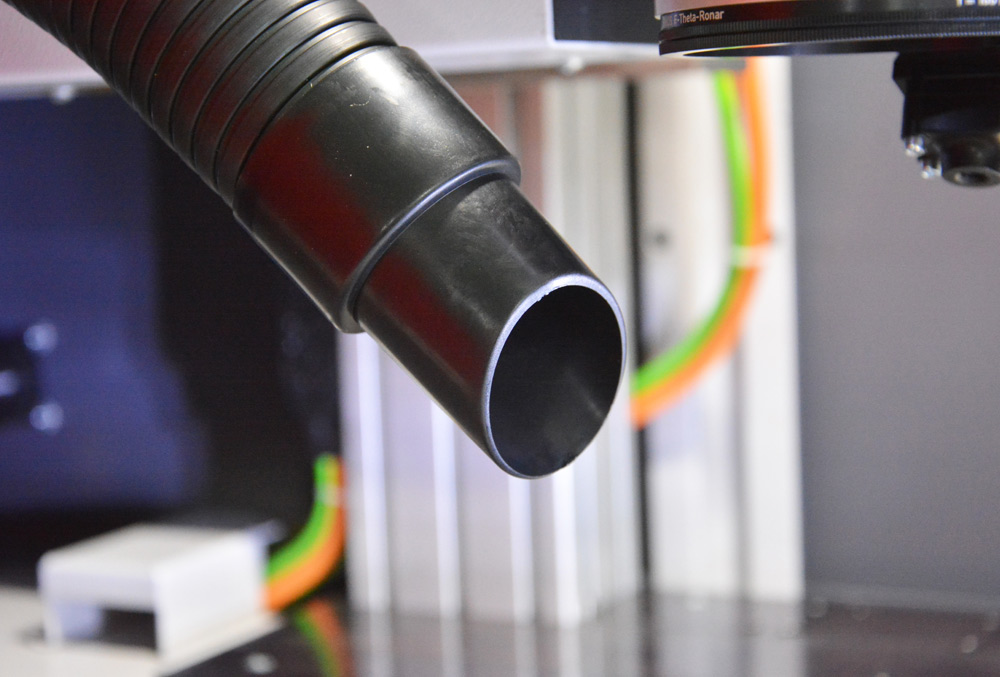

Fiber laser Decapsulation system BL5500 series

Features

- The entire process is 100% controllable by the operator, allowing one to determine the precise depth, location, and geometry of the ablation area through our User Interface.

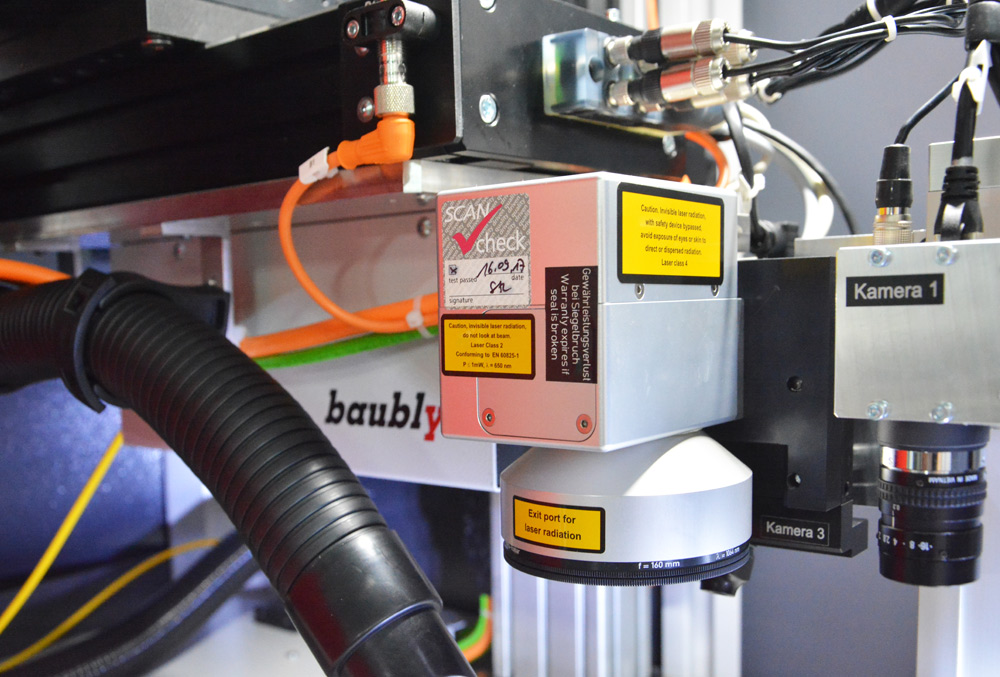

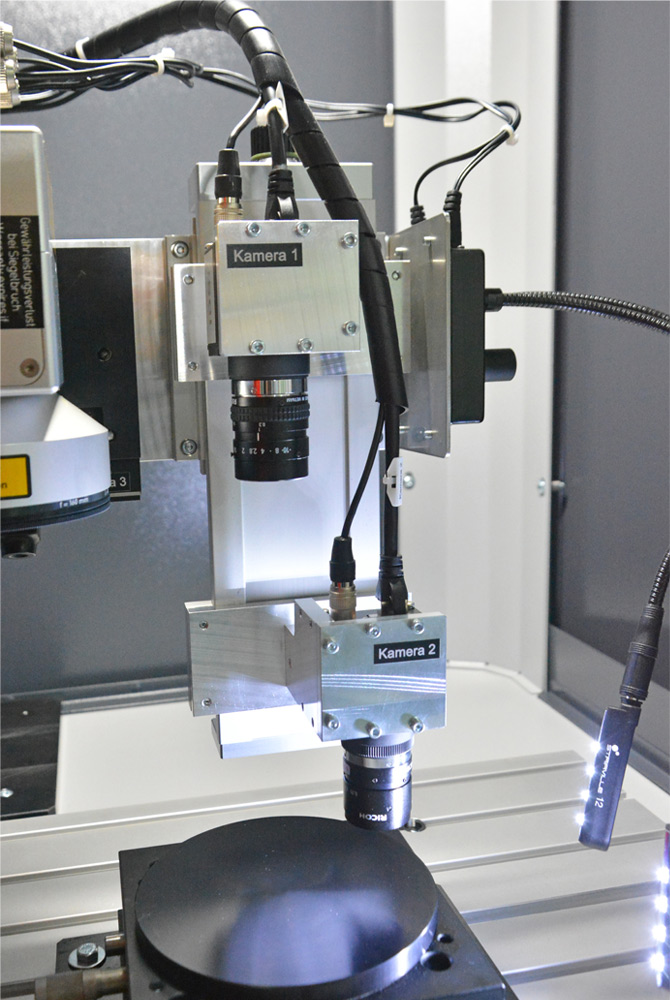

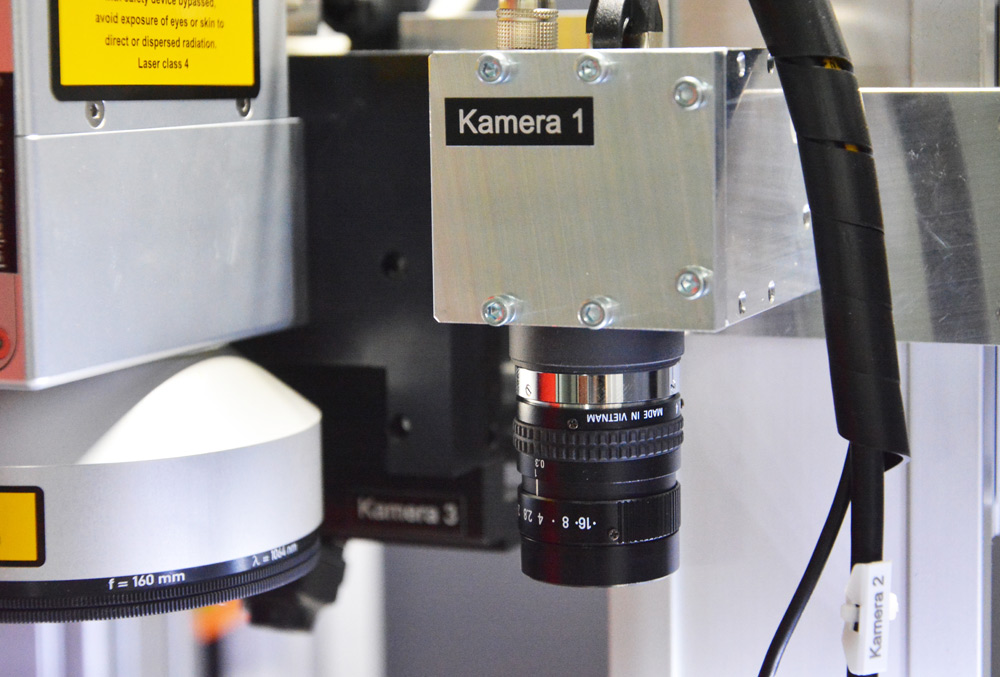

- Real time color vision system provides a continuous control of the ablation process.

- Three fully CNC controlled axes and two 5Mp independent high resolution Ethernet cameras ensure the precise positioning.

- Integrated red laser pointer for comfortable adjustment and positioning of the work piece.

- No destruction of wires during opening

- Laser class one safety cabinet, no additional cost for laser protection.

Application

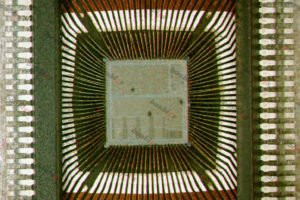

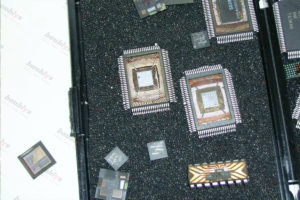

- Semiconductor failure analysis; IC decapsulation and removing large filler mold compounds, such as revoe resin and plastics; Expose Wire Bonds

Specifications

| Laser type | Ytterbium fiber laser |

| Wavelength | 1064 nm |

| Pulse repetition frequency | 1.6 kHz – 1 MHz |

| Pulse width | 4 – 200 ns |

| Power | 20 W |

| Inscription area | max. 300 x 300 mm |

| Control | CNC control |

| System software | Windows 7 |

| Measurements | 1493 x 860 x 1777 mm (L x W x H) |

| Network connection | Yes |

Samples

laser decaping

laser decaping

laser decaping

laser decaping

Materials

| Material | Engrave |

| Stainless | √ |

| Coated Metals | √ |

| Anodized Aluminum | |

| Brass | √ |

| Copper | √ |

| Gold | √ |

| Silver | √ |

| Titanium | √ |

| Bare Metals | √ |

| Ruber | √ |

| PP | √ |

| PS | √ |

| PP | √ |

| ABS | √ |

| PVC | √ |

| PE | √ |

| Acrylic | |

| MDF | |

| Wood | |

| Granite | |

| Marble | |

| Brick | |

| Glass | |

| Fiber Glass | |

| Crystal | √ |

| Ceramic | √ |

| Diamond | √ |

| Gemstone | √ |

| Cloth | √ |

| Leather | √ |

| Fiber | √ |

| Carbon Fiber | √ |

-1.jpg)